When it comes to getting the best possible performance from a component made of metal or plastic, taking the time to apply an appropriate surface treatment is key. That’s because treating the surface correctly will deliver a number of benefits that can improve the life cycle of a part, or enhance its capabilities, including providing resistance to corrosion, extremes of temperature, and general wear and tear.

Choosing the right type of treatment is important, and five of the most popular options are cleaning, polishing, painting, plating, and heat. You can discover some of the latest applications for the process at.

Cleaning and Polishing Treatments

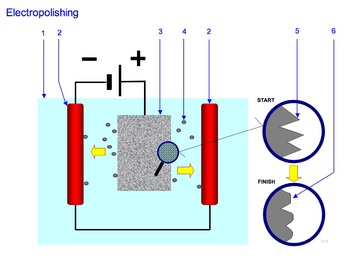

This type of surface treatment sees the surface undergo a process to ensure that it is completely free of oils, dust, debris, burrs, and oxides. This means that the durability of later painting and plating treatments is optimised. Some cleaning processes also include the use of blasting and honing of the surface, with abrasives being applied in order to ensure the smoothest possible end result. This kind of cleaning treatment overlaps with polishing treatments, in which the surface is smoothed through either mechanical, chemical, or electropolishing techniques.

Painting Treatments

Here, the surface is covered with paint through spray, electrostatic and electrodeposition application techniques. Whilst this treatment helps to defend the component from corrosion such as rust, it is also commonly used as a decorative process.

Plating Treatments

Robust protection can also be provided by plating treatments, in which thin layers of metal are applied to the substrate via electroplating, hot dip, and chemical methods. Thermal plasma spray treatments are a popular option in this category, and you can learn more about this versatile process at specialist sites such as www.poeton.co.uk/advanced-treatments/apticote-800-thermal-plasma-spray/ Following the plating treatment, the finished surface will be highly durable, resistant to a variety of extreme environmental conditions, and strength is often enhanced, too. This treatment process can also be used as a way to improve the appearance of the component.

Heating Treatments

Heating treatments see a surface substrate treated with temperature in order to achieve improved hardness. This means that the surface will be more resistant to wear and tear and less easily fatigued as a result. The surface is heated to a high temperature before being cooled, in order to change the chemical structure of the material, a process which is achieved through surface quenching, charcoal burning, and nitriding treatments.